1.The FG series Boiling Fluid Bed Dryer can be widely used in pharmaceutical,chemical,foodstuff industry etc.

2.The FG series Boiling Fluid Bed Dryer is one of the standard process equipment in the solid preparation production.for example:the production of tablets,granules and other wet granules.

3.The FG series Boiling Fluid Bed Drye has many fuctions.such as mixing,granulating etc.and used for fast dry & wet mixing, homogenizing,humidifying and granulating of the powder.

Application:

1.The FG series Boiling Fluid Bed Dryer can be widely used in pharmaceutical,chemical,foodstuff industry etc.

2.The FG series Boiling Fluid Bed Dryer is one of the standard process equipment in the solid preparation production.for example:the production of tablets,granules and other wet granules.

3.The FG series Boiling Fluid Bed Drye has many fuctions.such as mixing,granulating etc.and used for fast dry & wet mixing, homogenizing,humidifying and granulating of the powder.

Working principle:

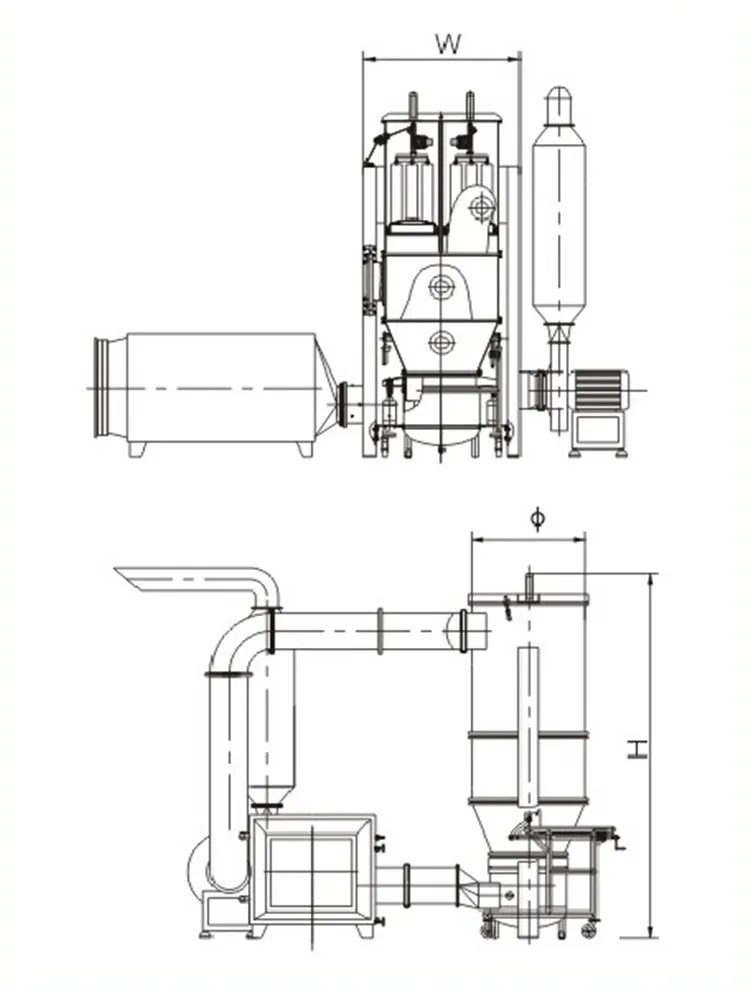

1.The FG series Boiling Fluid Bed Drye is composed of main machine (processor), air handling unit(AHU), heating and control systems. When operating, charge the materials into the Bowl, set the procedure and parameters according to process requirements

2.Start the processor.The inlet air is filtered by the air handling unit(AHU)and heated by the heating system

3.The processed air enters the processor to blow up materials into fluidization condition. Materials are apace dried and moisture rapidly vaporized.

4.When the operation has been finished; Move out the Bowl to lock with pharma Lifter for FBD/FBG Bowl for lifting and discharging the produced granules.

5.During the whole process, powder dust and cross pollution are effectively controlled.

Features:

1.The advanced technology design with high drying efficient.

2.Reasonable structure and stable performance,Closed sampling fnction

3.Easy operation

4.No dead corner or protrudded

5.High quality SUS316,SUS304 stainless steel.

6.PLC designed to ensure a fully automatic control.

7.Process parameters can be printed and original data are reliable.

8.Meets FDA/GMP requirements

9.Passed CE/CQC certificate

10.CIP online cleaning system can be chosen to install

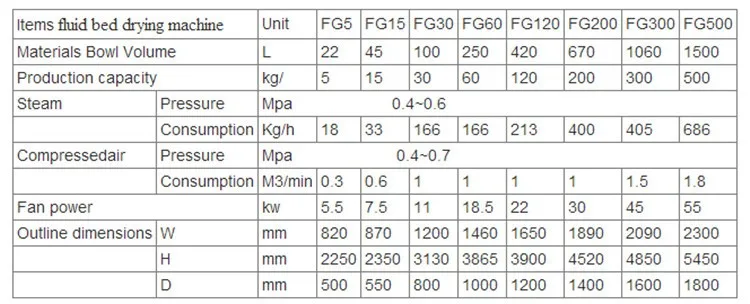

Technical Parameter

Welcome to our website! Please send your words at any time in the following form and ask us, we will contact you and provide you with the corresponding service as soon as possible. Please write in English.

GFG Cheese Powder Flake Fluid Bed Processor is the granule high-efficient drying equipment which is matched with YK Type Swing Granulator or GHL Type High-speed Mixing Granulator. It has more fluidized range than traditional horizontal XF fluidized drier and can be easily cleaned. When fluidized, the material is stirred slowly avoiding the block. So it has special advantages for the high wet and sticky material.

Learn MoreThe powder granule in fluid bed appears in the state of fluidization. It is preheated and mixed with clean and heated air. At the same time the solution of adhesive is sprayed into the container. It makes the particles become granulating that contains adhesive. Being of unceasing dry through hot air, the moisture in the granulating is evaporated. The process is carried out continuously. Finally it forms ideal, uniform and porous granules.

Learn MoreDrying for wet granules and powder materials of screw extruded granules, swaying granules, high-speed mixing granulation in the fields such as Pharmacy, food, feed, chemical industry and so on. Large granules, small block, viscous block granular materials. The materials such as Konjak, polyacry lamide and so on, which will have the volume changed during drying.

Learn MoreThe powder granule in fluid bed appears in the state of fluidization. It is preheated and mixed with clean and heated air. At the same time the solution of adhesive is sprayed into the container. It makes the particles become granulating that contains adhesive. Being of unceasing dry through hot air, the moisture in the granulating is evaporated. The process is carried out continuously. Finally it forms ideal, uniform and porous granules.

Learn More